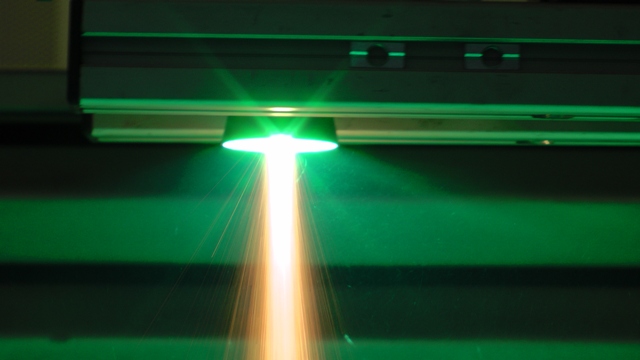

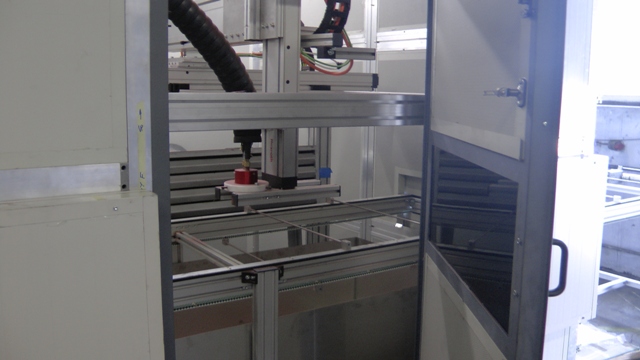

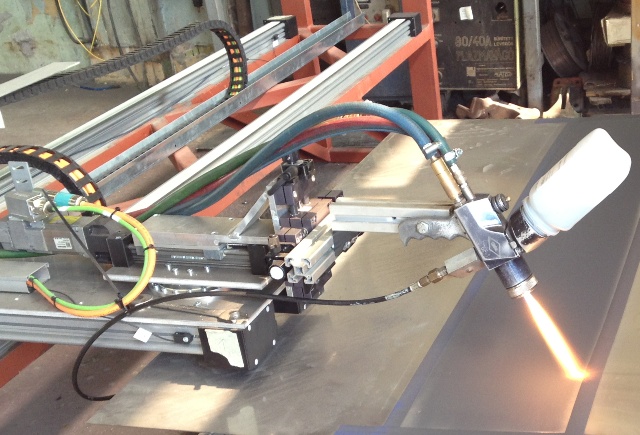

MOGUL METALLIZING GMBH offers complete system for torch and parts manipulation. Our integrated systems use the same control unit (mainly Siemens S7) for the thermal spray equipment, gun and parts manipulation.

Furthermore we offer sound-protection chambers, exhaustion and filter units as well as blasting devices.

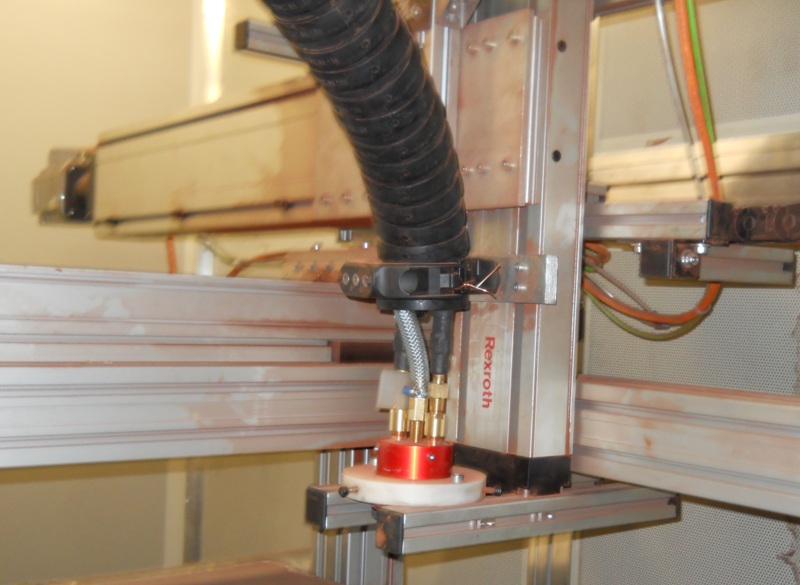

Torch-manipulation - Depending on the complexity of the work-piece several axis of movement will be necessary.

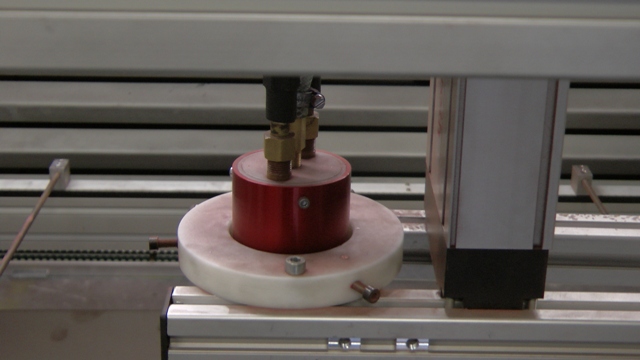

Parts-manipulation – Depending on the kind of work-piece and the required grade of automation turn/tilt tables (also adjustable in height) with varying maximum loads or other manipulation devices are used. Our tilting turntables are less limited in tilt degrees than those of our competitors.Another issue is loading and unloading of the work-pieces.

Sound-protection chambers – Thermal spraying is depending on the used procedure a very loud process. To ensure work safety it often makes sense to put the whole equipment in a sound-proof chamber.

Exhaustion- and filter units – To guarantee work safety as well as the quality oft he coating it is necessary to exhaust the resulting fumes as well as the not bonding particles. MOGUL offers suitable intake elements, exhaustion and filter units.

Blasting units – To prepare work-pieces for thermal spraying it is necessary to blast them. MOGUL offers mobile and stationary equipment for this purpose.